The role of calcium formate in gypsum mortar

The role of calcium formate in gypsum mortar,

Calcium Formate, calcium formate action, Calcium Formate Manufacturers, Calcium Formate Uses, cement additives,

1. Basic information of calcium formate

Molecular formula: Ca(HCOO)2

Molecular weight: 130.0

CAS NO: 544-17-2

Production capacity: 60,000 tons/year

Packaging: 25kg paper-plastic composite bag

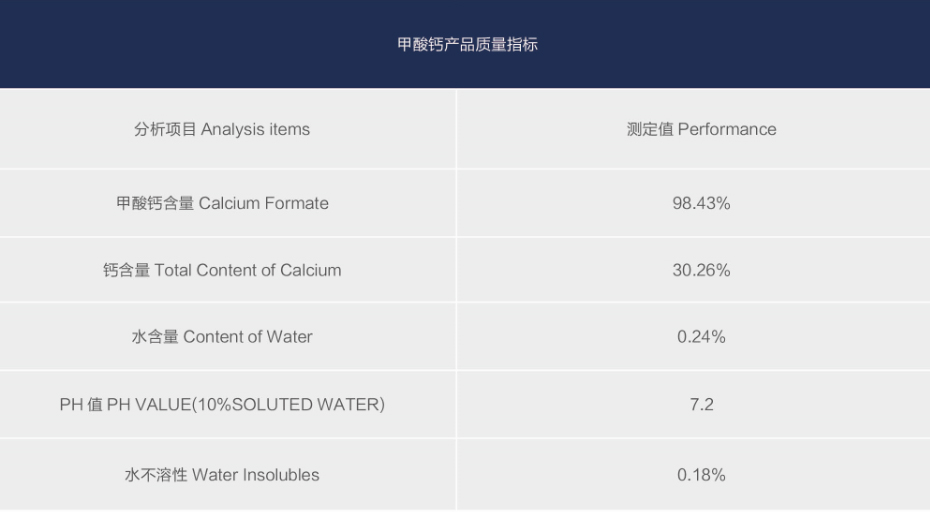

2. Product quality index of calcium formate

3. Application scope

1. Feed grade calcium formate: 1. As a new type of feed additive. Feeding calcium formate to gain weight and using calcium formate as a feed additive for piglets can promote the appetite of piglets and reduce the rate of diarrhea. Adding 1% to 1.5% calcium formate to the piglet diet can significantly improve the performance of weaned piglets. A German study found that adding 1.3% calcium formate to the diet of weaned piglets can improve the feed conversion rate by 7% to 8%, and adding 0.9% can reduce the incidence of piglet diarrhea. Zheng Jianhua (1994) added 1.5% calcium formate to the diet of 28-day-old weaned piglets for 25 days, the daily gain of piglets increased by 7.3%, the feed conversion rate increased by 2.53%, and the protein and energy utilization rate increased by 10.3% respectively. and 9.8%, piglet diarrhea was significantly reduced. Wu Tianxing (2002) added 1% calcium formate to the diet of ternary hybrid weaned piglets, the daily gain was increased by 3%, the feed conversion rate was increased by 9%, and the piglet diarrhea rate was reduced by 45.7%. Other things to note are: the use of calcium formate is effective before and after weaning, because the hydrochloric acid secreted by the piglets increases with age; calcium formate contains 30% easily absorbed calcium, so pay attention to adjusting calcium and phosphorus when formulating feed. proportion.

2. Industrial grade calcium formate:

(1) Construction industry: as a quick-setting agent, lubricant and early-drying agent for cement. It is used in construction mortar and various concretes to speed up the hardening speed of cement and shorten the setting time, especially in winter construction, to avoid too slow setting speed at low temperature. The demoulding is fast, so that the cement can be put into use as soon as possible.

(2) Other industries: tanning, wear-resistant materials, etc.

Application

1. Feed Grade Calcium Formate:Feed Additives

2. Industry Grade Calcium Formate:

(1)Construction Use:For cement, as coagulant,lubricant;Forbuilding mortar,to acceleration cement’s hardening.

(2)Other Use:For leather, anti-wear materials,etc

Calcium formate is a very common material additive in the decoration process. Its addition can improve the performance and stability of gypsum mortar. So what are the advantages of calcium formate in gypsum mortar?

Calcium formate is a very common material additive in the decoration process. Its addition can improve the performance and stability of gypsum mortar. So what are the advantages of calcium formate in gypsum mortar?

First, calcium formate can accelerate the rate of gypsum condensation. Gypsum mortar requires a certain setting time during the construction process to ensure that the mortar can be fully cured and hardened. Adding proper amount of calcium formate can delay the setting rate of gypsum mortar, so that the construction personnel have enough time to operate and adjust, so as to improve the construction efficiency.

Secondly, calcium formate has a significant effect on the strength and hardness of gypsum mortar. Calcium formate in gypsum mortar can react with hydration hardening products in gypsum to form a more stable crystal structure. This reaction can enhance the strength and hardness of gypsum mortar, making it more durable and stable. At the same time, calcium formate can also improve the cracking resistance of gypsum mortar and reduce the cracking problem caused by dry shrinkage.

In addition, calcium formate can also improve the water resistance and durability of gypsum mortar. When gypsum mortar encounters moisture or humidity, it is easy to soften and dissolve. By adding an appropriate amount of calcium formate, it can react with water to form a stable substance, so that the ability of gypsum to resist water erosion has also been greatly improved. In this way, even if it is in the plum rain or other extreme wet weather for a long time, it is not easily affected by humidity changes.

In addition, calcium formate can also improve the workability and construction performance of gypsum mortar. After adding calcium formate, the fluidity and viscosity of gypsum mortar are improved, which makes the construction more convenient. The construction personnel can better control the fluidity and cohesiveness of the mortar, so as to obtain a more uniform and smooth construction effect.

Therefore, the role of calcium formate in industrial engineering processing is not to be underestimated. It can shorten the setting time of gypsum mortar as much as possible, increase the strength and hardness of mortar, improve water resistance and durability, and also improve workability and construction performance. Therefore, when using gypsum mortar, adding calcium formate is an effective improvement method, which can improve the quality and performance of mortar and meet the needs of different building decoration.